CREATING AN INTRINSIC AND IMMUTABLE LINK BETWEEN A PRODUCT AND ITS DATA TO ASSURE TRACEABILITY, SECURITY AND AUTHENTICITY

WHAT IS A vTAG®?

Like a human fingerprint or iris scan, a vTag® uses intrinsic surface features of an item to uniquely identify it from all other items of its kind.

DELIVERING IMPACT IN EVERY INDUSTRY WE SERVE

Covisus keeps users safe by ensuring that their products meet stringent Government regulations designed to ensure their authenticity and traceability in the event of a recall. Our customers operate in a wide range of regulated industries with unique needs and requirements. These industries include:

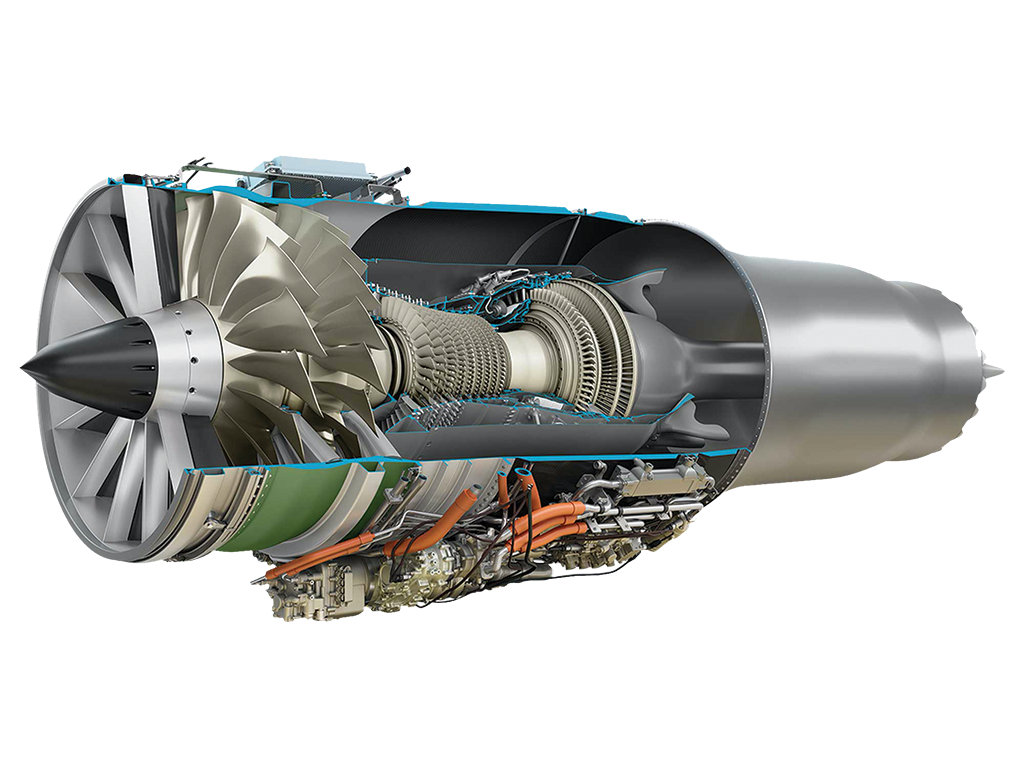

aerospace

Covisus vTag® offers full compliance with the Department of Defense mandates on Item Unique Identifiers (IUID) DFARS 252.211-7003 that mandates that critical military components be fully traceable.

vTag® enables full traceability, for the first time, for critical components that cannot be physically tagged because of their operational environment, such as aircraft engine hot-section parts.

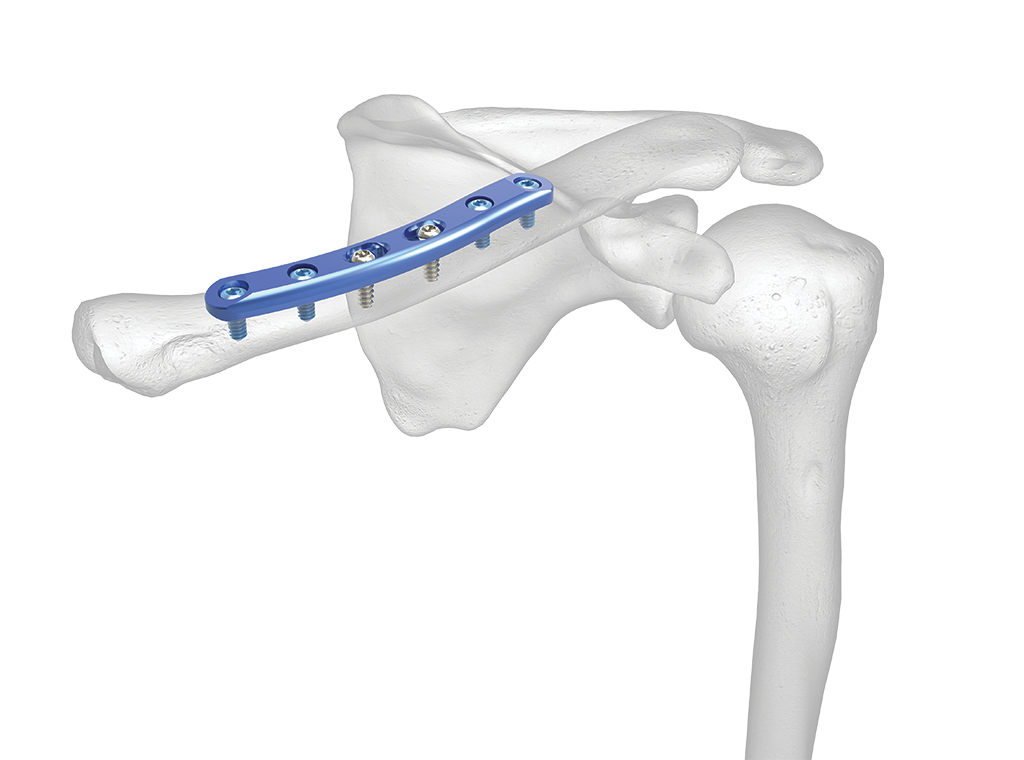

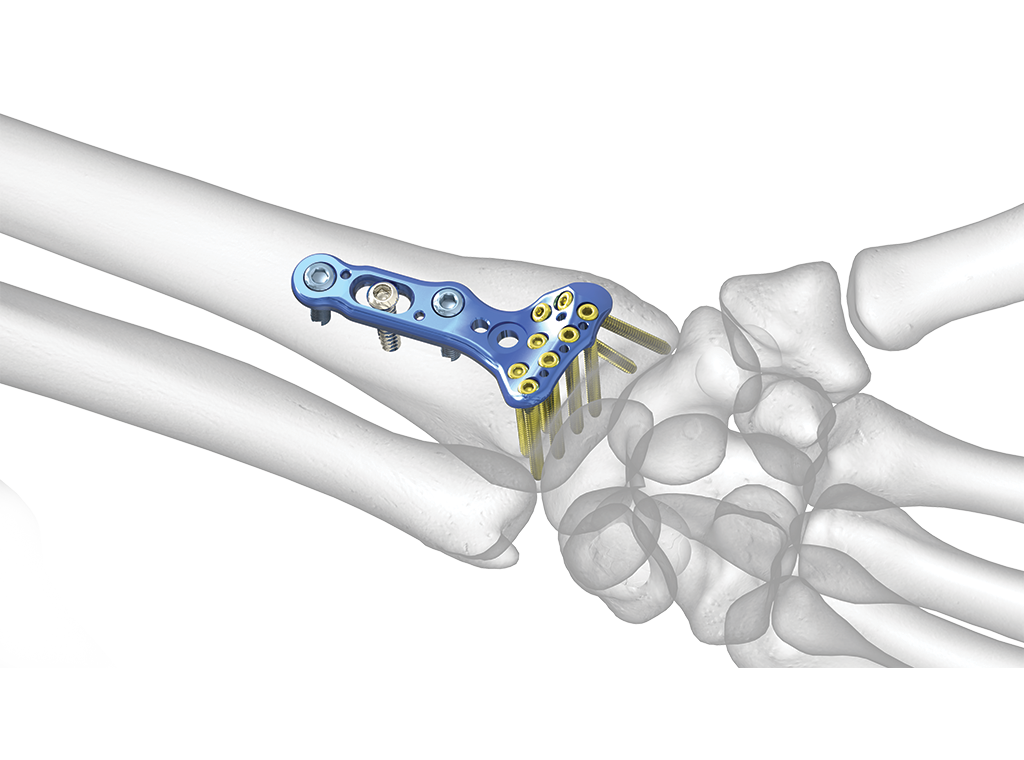

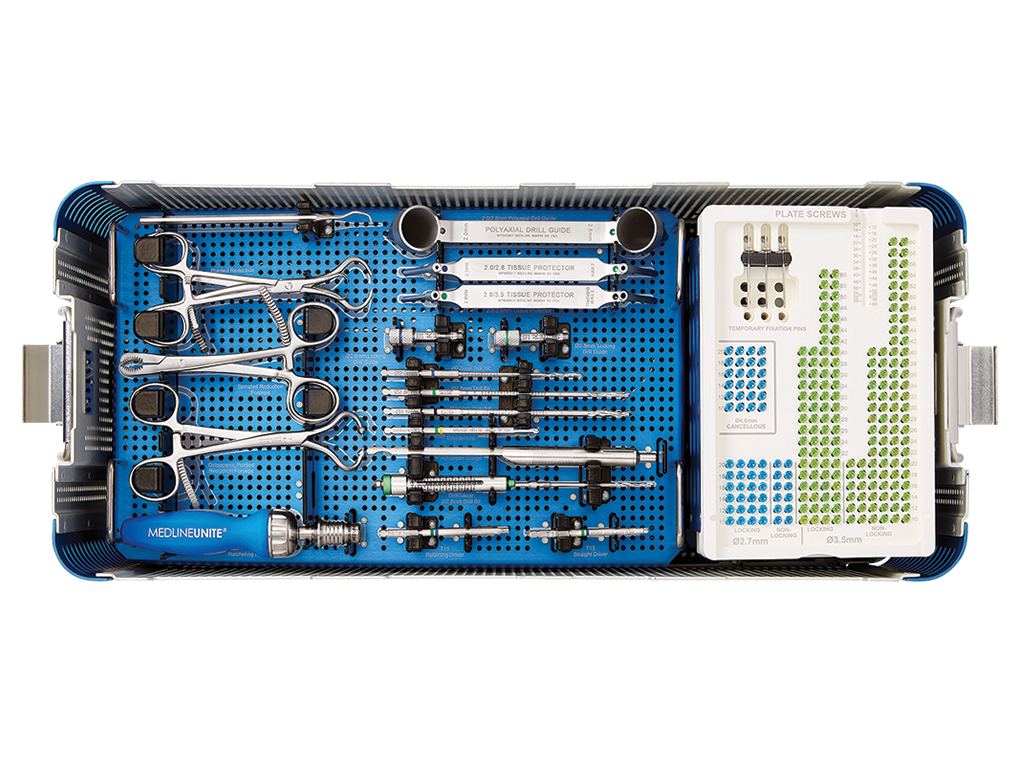

medical deviceS

Covisus vTag® offers full compliance to the US Food And Drug Administrations (FDA) Unique Device Identifier (UDI) regulation 21 CFR 801.30 that requires all medical devices to be traceable to a patients medical records to ensure patient safety during a recall.

vTags® enable, for the first time, full traceability of orthopedic implants that are too small to be direct part marked with a UDI label.

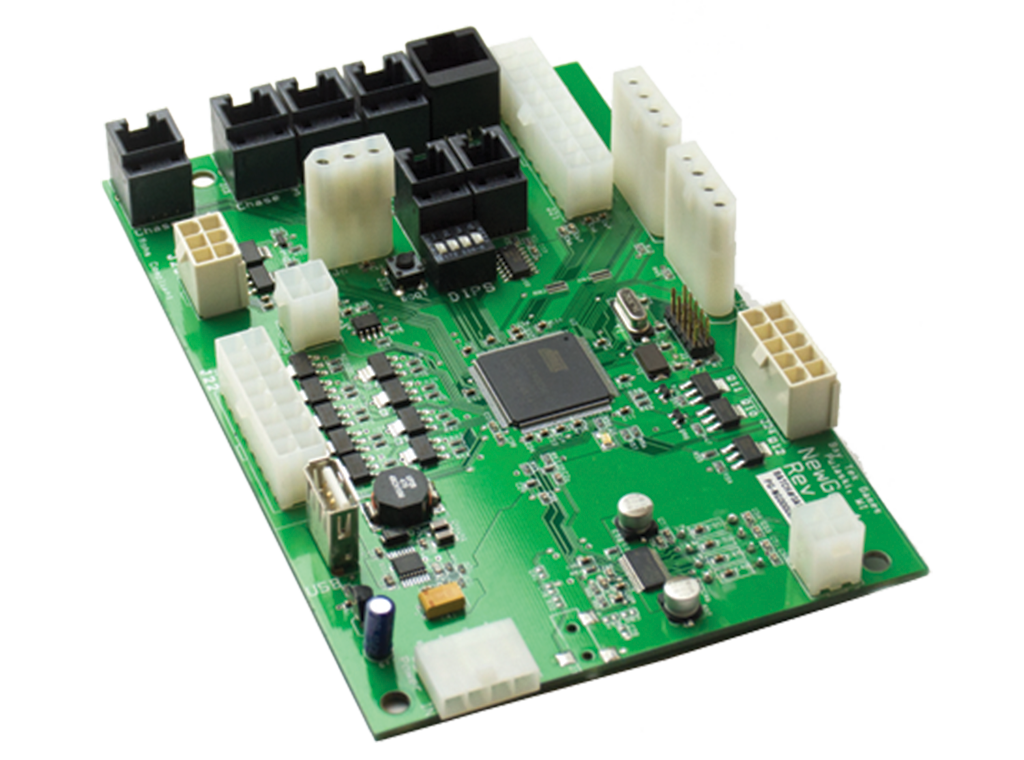

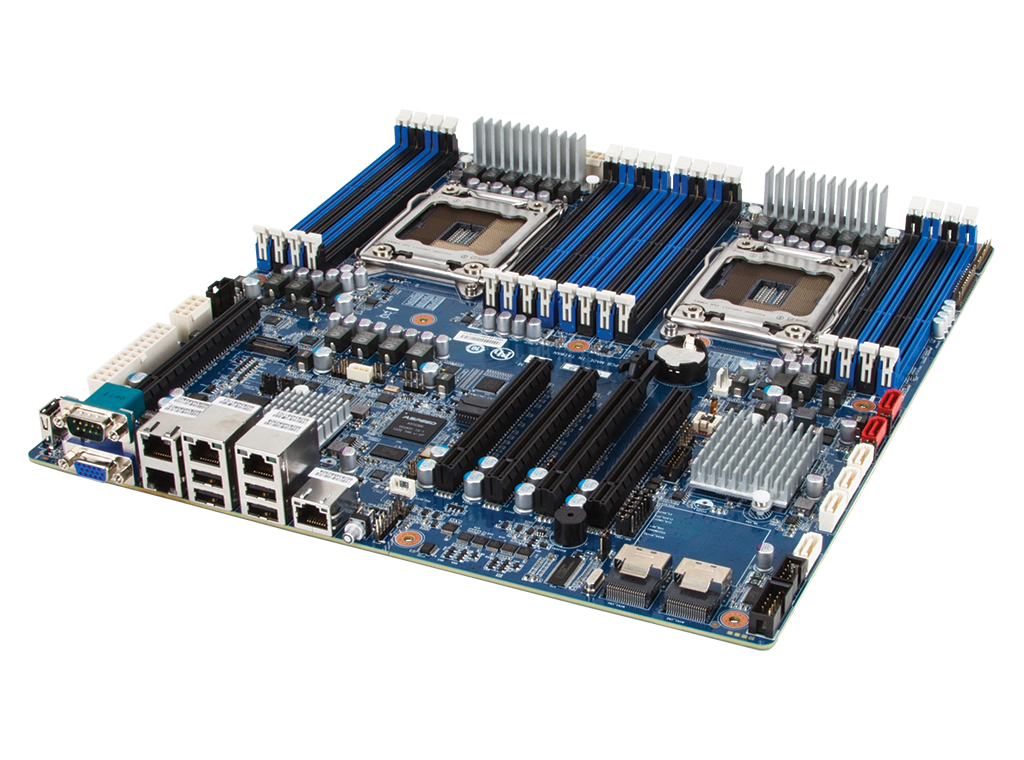

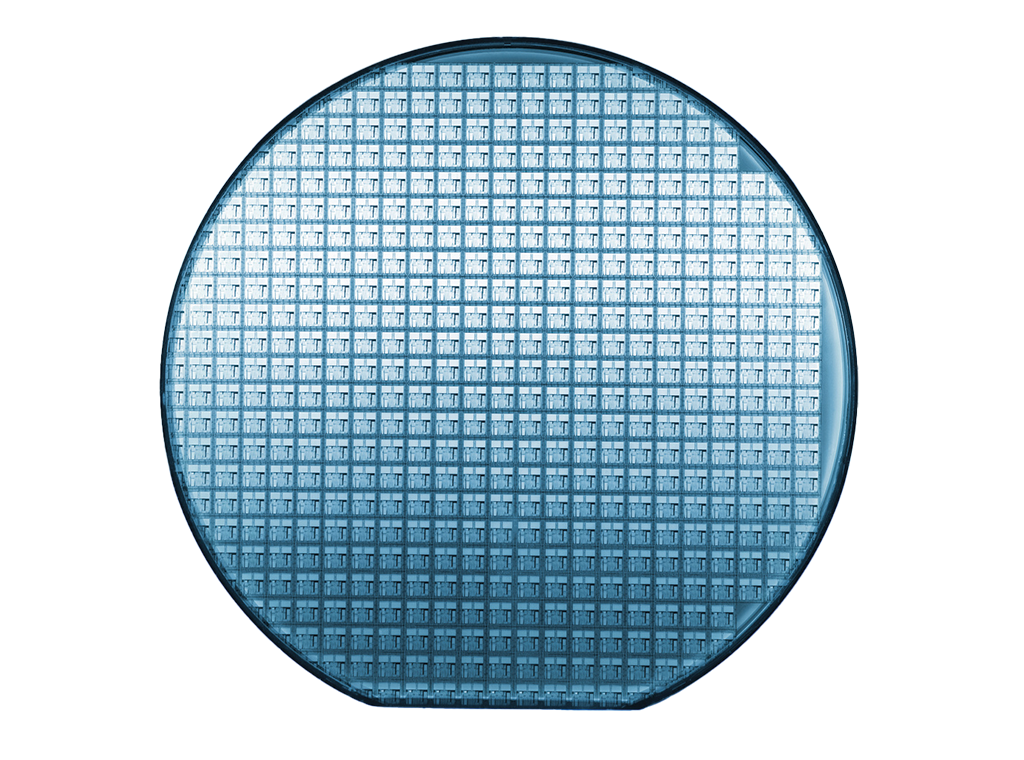

microelectronics (DEFENSE)

Covisus vTags have been developed to meet the US Department of Defence “Zero Trust” posture on microelectronics.

vTag based systems automate AS-6171 visual inspection of microelectronic components to ensure their authenticity.

vTags can track and trace a microelectonic component from wafer, to die, to package to a printed circuit board assembly (PCBA). We enable the Department of Defence to reduce costs associated with testing of components and the time it takes to rework PCBAs.

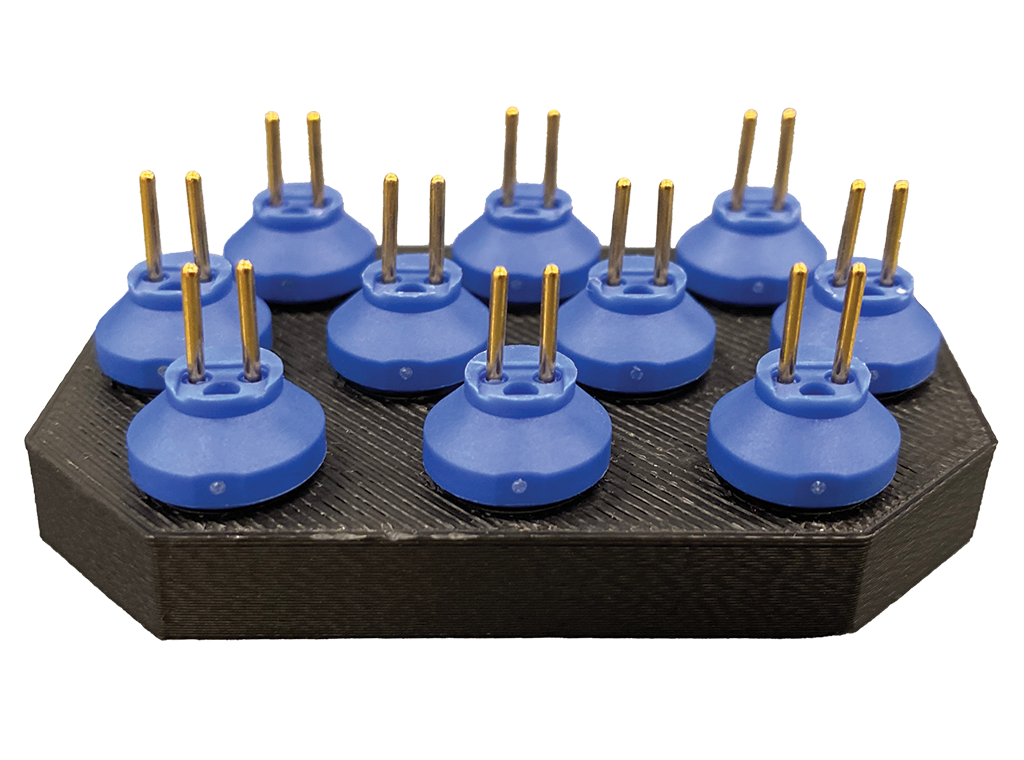

manufacturing

vTags® can be applied to components as small as 0.5mm, such as the leads of airbag charge initiators. With takt times of less than 2seconds, we integrate IoT sensor data with a component and enable Industry 6.0.

SOLUTION BENEFITS

Our Proven vTag® technology addresses three key supply chain challenges Without introducing any additive markings or modifications to the item.

TRACEABILITY

The vTag® technology is currently being adopted by the medical device and military/aerospace communities to meet regulatory traceability requirements. The vTag® solution has been proven to be portable and cost effective. It has been validated by numerous Federal (US) institutions and Fortune 100 companies.

SECURITY

Unlike other tagging solutions, such as barcodes and RFID, a vTag® relies on the intrinsic randomness of a products surface texture at the micrometer scale. As a result it is covert and unforgeable. Items secured with vTags® provide the highest level of security and cannot be forged or replicated.

AUTHENTICITY

vTags® keep your products and brands safe by ensuring that they are not tampered with or counterfeited. Without changing your current production or packaging processes, vTag® provides end-to-end security across your disturbed supply chain.

Features include:

Features include:

- Comparative surface characteristic analysis

- Measuring visual features of an item

- Checking against specifications

- Reporting on non-compliant features/anomalies

FREQUENTLY ASKED QUESTIONS

1. J. Buchanan, R. P. Cowburn, et al, “”Fingerprinting” documents and packaging, “Nature, Vol 436, PP. 475, 2005.

A vTag® will work with rigid items of any size or shape as long as its surface is not modified between enrollment and authentication. Examples include items made from metals, plastic, rubber and wood that are fabricated through any existing processes (including additive manufacturing) and have a durable finish (including paints).

Spelling does not always determine a words proper pronunciation. Covisus may be confusing for some to pronounce. To help with that, here are some examples:

Co•vi•sus / Co•vie•sus / Co•vye•sus

Please contact us with your specific product or work environment so that we can provide you with more details on how vTag® can work for your unique requirements. Contact Us

IN THE NEWS

Recent Posts

OUR VALUED PARTNERS