DTEK

Microelectronic Optical Scanning

Covisus has developed DTEK to meet the ongoing challenges to ensure the authenticity and security of microelectronic parts within its supply chain. We have developed this solution to be a cost effective, rapid, and practical solution that uses machine learning and machine vision to identify and tag suspect components rapidly. This scalable solution stack is easy to implement and use across the supply chain by easily integrating into existing manufacturing processes, with minor modifications to existing hardware.

We developed a rapid, portable, surface texture based component classier system that will rely on machine learning based algorithms to instantly identify if a microelectronic component has been re-marked, and/or if the component is a counterfeit not produced by the original component manufacturer (OCM).

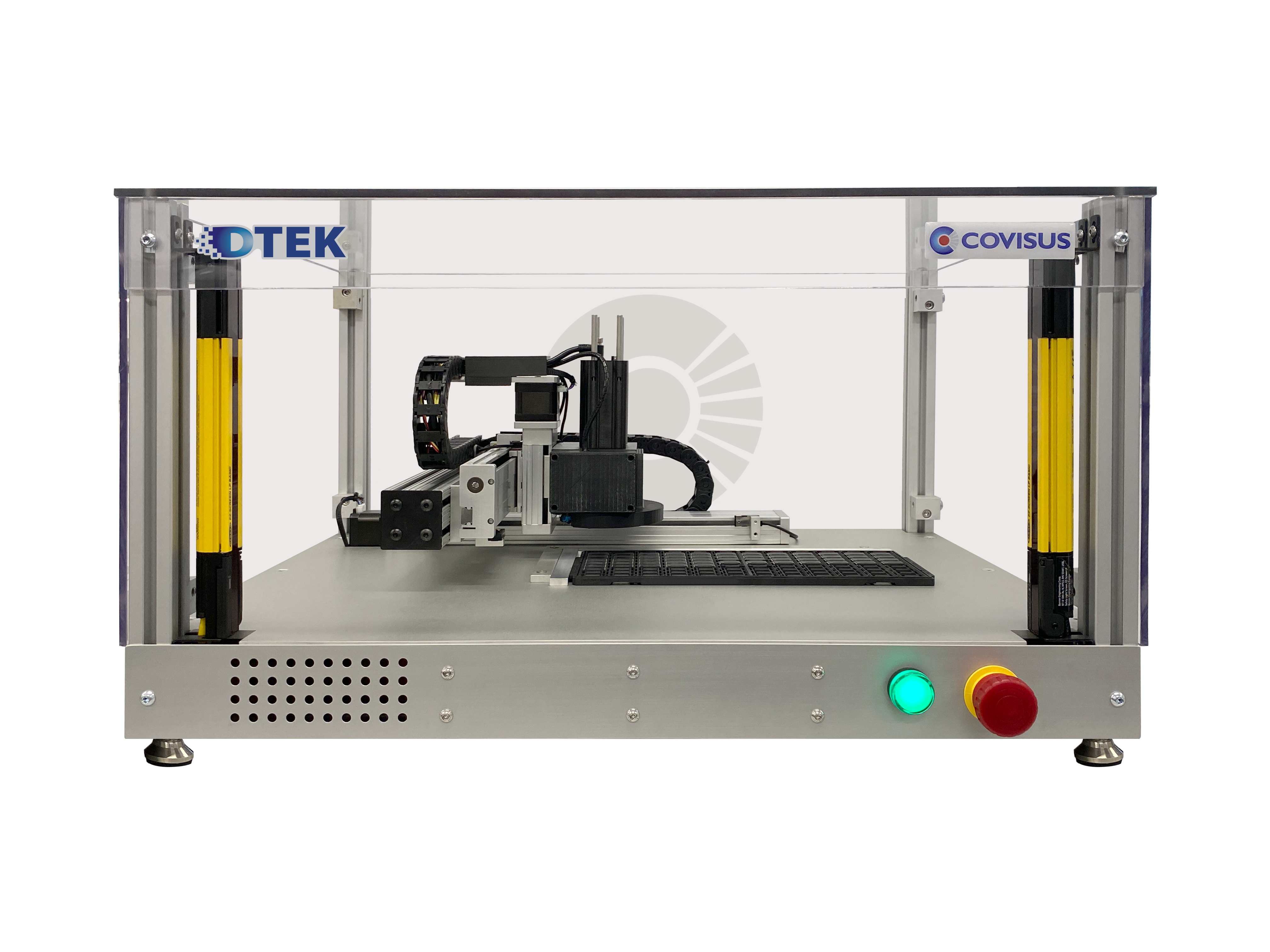

DTEK Solution

DTEK 3.0 offers users a solution that reduces the time and improves tester-to-tester consistency of AS6171/2 Techniques for:

- Suspect/Counterfeit EEE Parts Detection by External Visual Inspection

- Remarking and Resurfacing

- Surface Texture Analysis tests

DTEK technology addresses key supply chain challenges by providing evidence of the product’s originality.

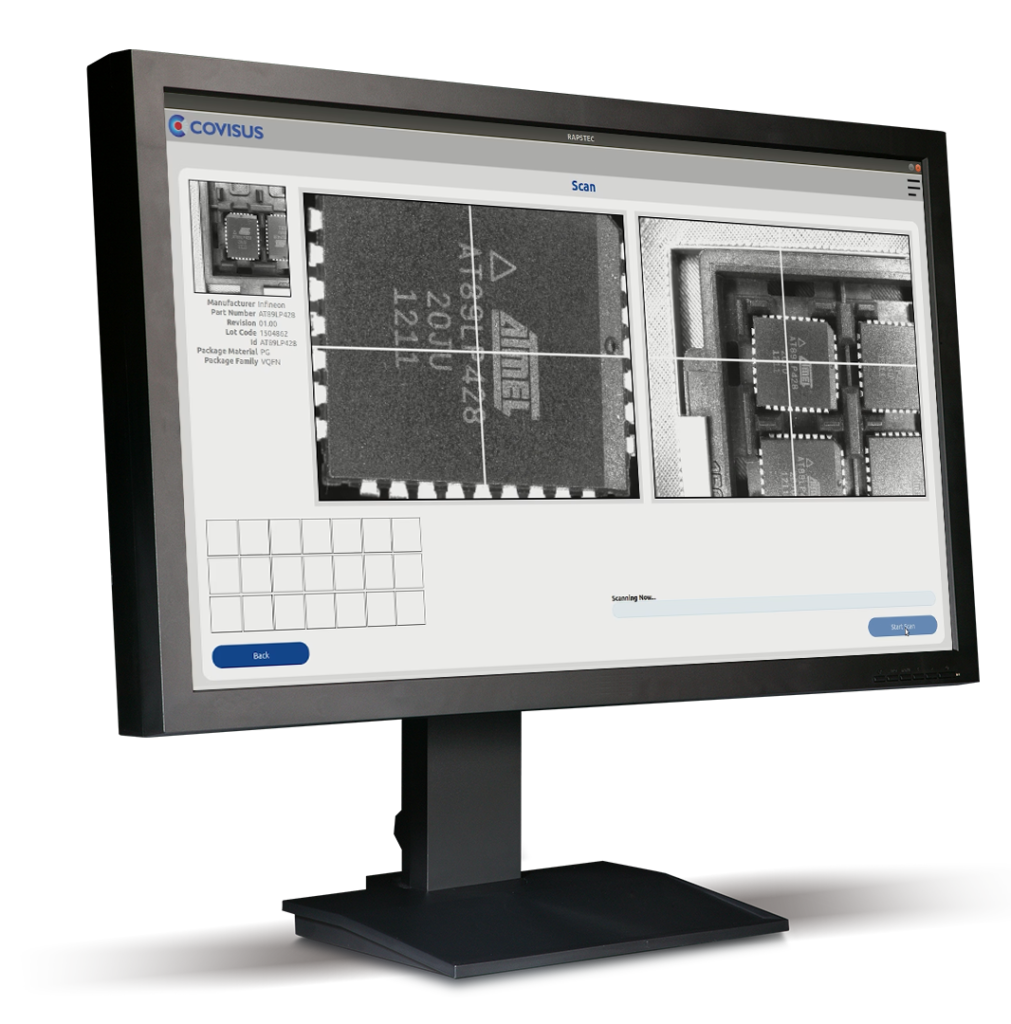

Using the DTEK user interface, part identification information is entered to add the part to the system. Images collected by DTEK are used to develop a machine-learning upgrade to the system.

The system will also include the option for surface texture analysis and part vTagging. Reporting generated to identify authentic or suspect parts for their authenticity.

TECHNOLOGY

We have developed our proven technology vTag® as a method for tagging and authenticating any object. Through scanning the intrinsic surface features of an object, we create a unique identifier (vTag®) that meets item level tracking and traceability requirements (QuanTEK). This technology can also be applied to item classication (DTEK) through our proprietary machine learning algorithms.

EASY INTEGRATION

Our systems are easily integrated into your existing manufacturing process. Validated APIs feed data into your existing ERP systems. Minor modications to existing hardware.

ROBUST ALGORITHMS

Our algorithms are not impacted by environmental factors to which the item is qualified, such as MIL-STD-883E and JEDEC Standard for Mark permanency.

- Patented scanner based on an off-the-shelf camera and custom lighting creates the digital fingerprint and part classifier

- Turnkey solutions – Vertical SaaS stack supported with hardware configurations optimized for user needs

- High speed operation ~2-3 seconds/scan

- Software stack combines cloud & edge computing as required in the deployment

- Fully automated inspection

- AS6171 based testing (visual inspection)

- vTag® surface texture based lot inspection covered under AS6081

Available Applications and Configurations

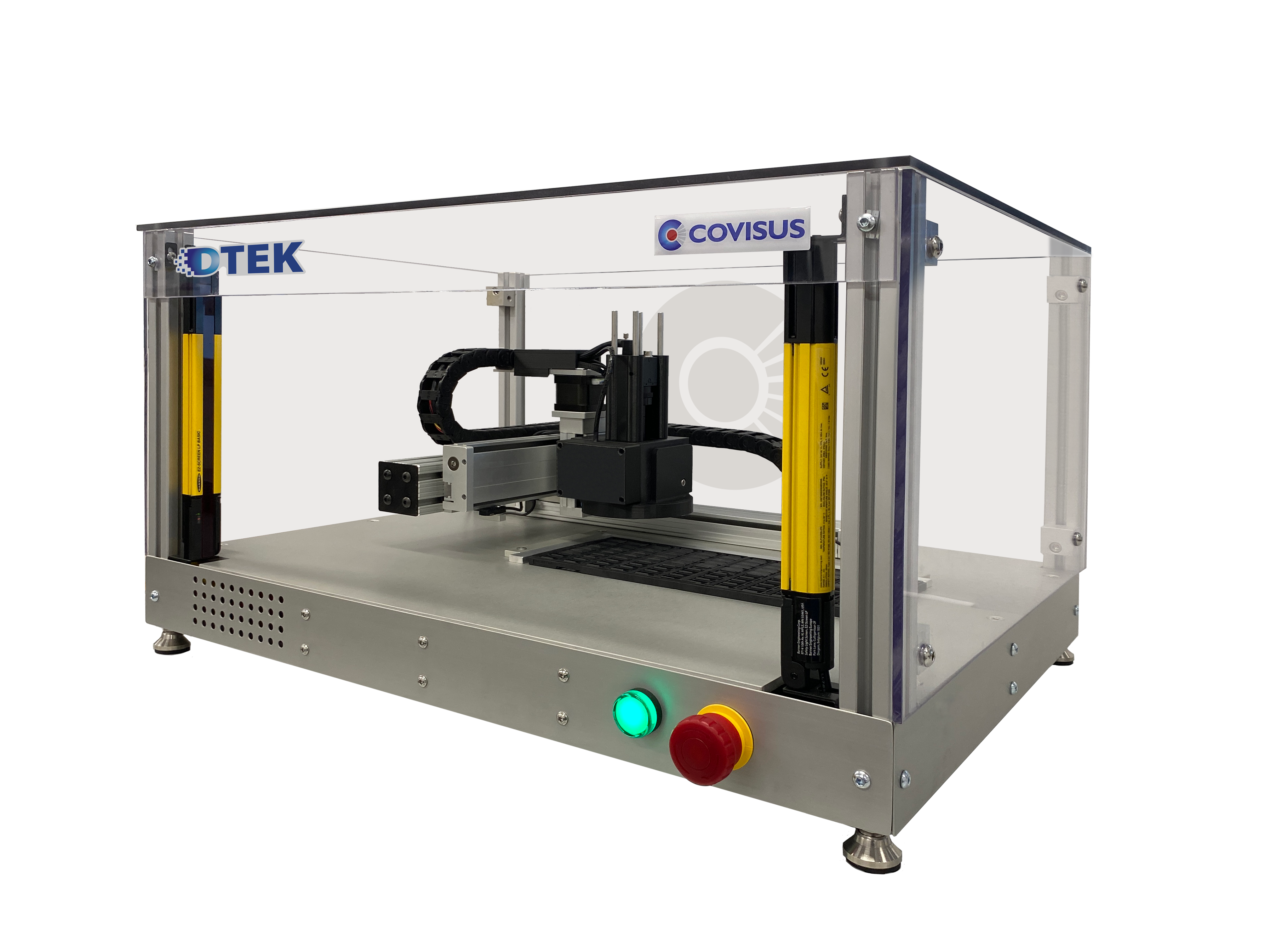

Both QuanTEK and DTEK systems are available in three main configurations designed to meet your operational needs. Examples of our handheld, portable, and high-throughput automated systems are shown below. Other custom configurations are available. Please contact us for more details.

Your company’s use case is unique with the product or brand that needs to be protected, verified, or tracked. Our highly skilled team of product and software engineers are at your disposal to work with your unique case to customize our product to fit your specific requirements. We encourage you to contact our team to discover the best solution for your system and processes.